Garlic is a pungent and flavorful bulb that has been an important ingredient in culinary traditions around the world for centuries. From pasta sauces to Indian curries, garlic can add depth and complexity to dishes. However, realizing its full potential in commercial food processing requires specialized equipment. In this blog, we will explore the necessary garlic processing equipment and its role in bringing this versatile ingredient to our tables.

- Garlic peeling equipment:

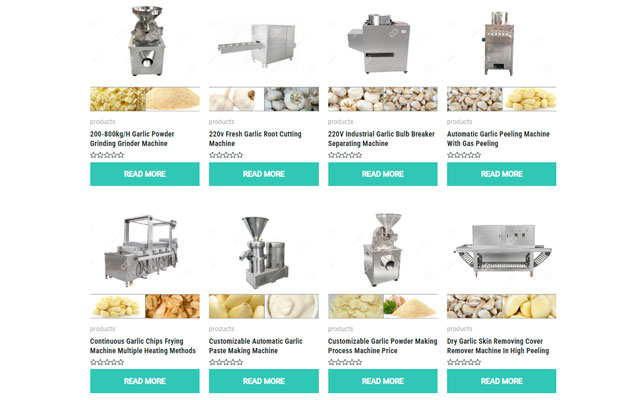

Let’s start with the beginning of your garlic processing journey – peeling it. Peeling garlic cloves by hand is tedious and time-consuming. This is where garlic peeling equipment comes into play. These machines can effectively remove the outer skin of garlic cloves, simplifying the production process and saving labor costs. - Garlic slicing equipment:

After peeling, the garlic cloves usually need to be sliced or chopped depending on the recipe. Garlic slicing equipment precisely cuts cloves into uniform thickness, ensuring consistent flavor and texture from batch to batch. These machines are adjustable, allowing for customization to specific cooking requirements. - Garlic grinding equipment:

For recipes that require mincing or pounding garlic, a grinder is essential. These machines crush garlic cloves into a fine paste, maximizing flavor dispersion in dishes. Garlic grinders are versatile and can efficiently process large quantities of garlic to meet the needs of commercial food production. - Garlic drying equipment:

Dried garlic products, such as garlic powder or garlic flakes, offer convenience and extend shelf life. Garlic drying equipment uses controlled heat and airflow to remove moisture from garlic cloves while retaining their flavor and nutritional properties. Dried garlic products are widely used in seasoning mixes, soups and sauces. - Garlic sorting and grading equipment:

Quality control is crucial in food processing. Garlic sorting and grading machines use advanced technology to inspect garlic bulbs for size, color and defects. By automating this process, these machines ensure that only high-quality garlic reaches the next stage of processing, thereby increasing overall product consistency. - Garlic packaging equipment:

Packaging is the final step in the garlic processing process. Garlic packaging machines efficiently weigh, fill and seal garlic products into a variety of packaging forms, including bags, sachets and jars. These machines provide precision and speed, allowing manufacturers to meet consumer demands while maintaining product freshness and integrity.

in conclusion:

From peeling to packaging, garlic processing equipment plays a vital role in the food industry, streamlining the production process and ensuring product quality and consistency. By investing in specialized equipment, food manufacturers can meet the growing demand for garlic products while delivering superior taste and convenience to consumers around the world. Whether it’s a delicious pasta sauce or an aromatic curry, garlic processing equipment helps bring out the best flavors in our favorite dishes, enriching the cooking experience one clove at a time.